Quality Management

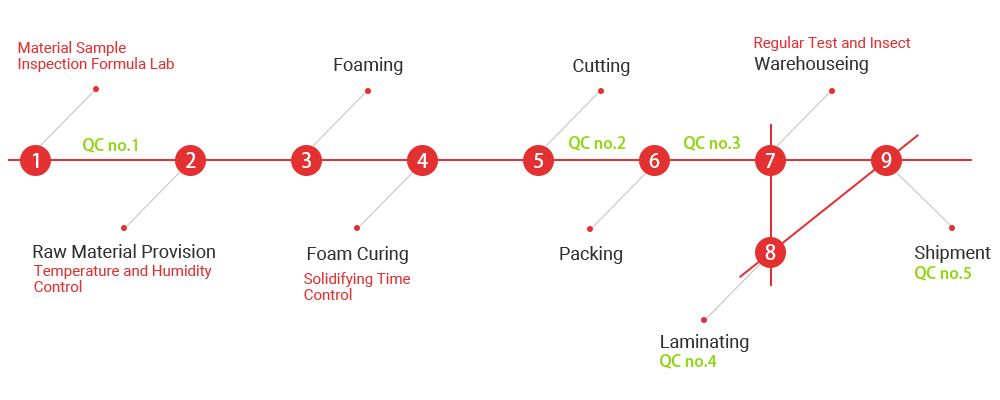

Quality Control Procedure

Quality checks all incoming materials under the standard procedure, including kraft paper, PE bag, core, blade, fabric, and TC fabric tested and inspected.

Inspection methods: visual, measurement, trial.

Visual

Measurement

Trial

Shipment inspection: inspection and confirmation for foam shipments

1

Use a needle detector to check for iron or metal.

2

According to the customer's request, the inspection will be carried out again. The inspection items include foam appearance, width, thickness, yellowing, quantity, label, packaging, etc.

3

Qualified shipment.